Mannekino

Patron

- Joined

- Nov 14, 2012

- Messages

- 332

I'm using a Dell PERC H200 HBA for my FreeNAS server. Today I added a Corsair Commander Pro to my system which also comes with a couple of temperature sensors. I want to properly monitor the temperature of my HBA. I've ordered a Noctua 40 mm PWM fan to mount on the heatsink and also some replacement thermal paste. I would like to monitor the temperature difference before and after mounting the new fan and replacing the thermal paste.

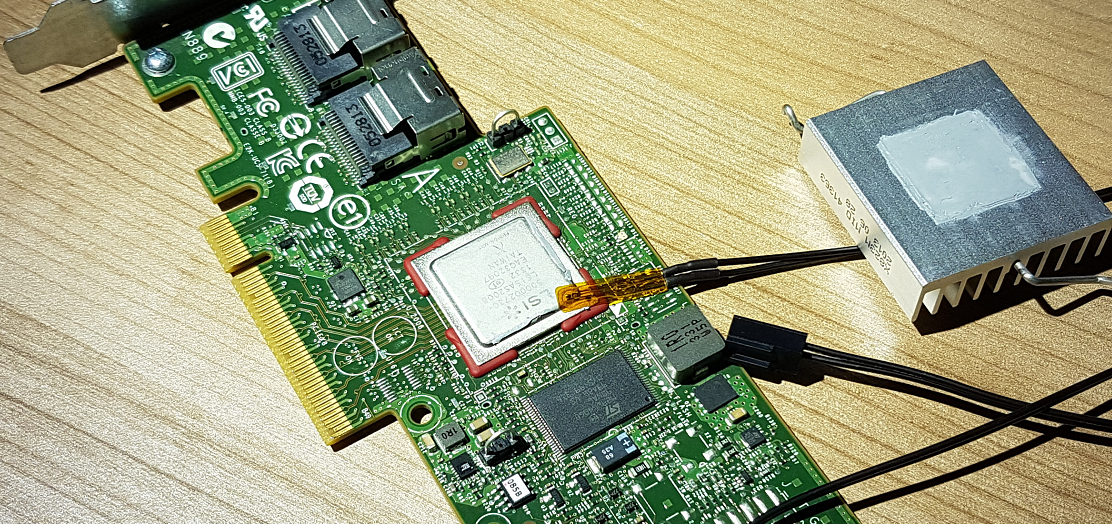

At the risk of this being an incredible stupid idea, I am thinking about doing the following. Below is a picture of an old Dell PERC H200 of mine that is defective. Would it be possible to put the tip of the sensor between the heatsink and the edge of the chip? Is this is good idea? It's the only location I can think of to get a consistent measure before and after. The sensor is very thin. Or perhaps I can somehow glue it on that little edge where the heatink doesn't touch the chip as an alternative?

Right now for testing purposes I've put a sensor between the fans of the heatsink and the readout is 44 °C.

At the risk of this being an incredible stupid idea, I am thinking about doing the following. Below is a picture of an old Dell PERC H200 of mine that is defective. Would it be possible to put the tip of the sensor between the heatsink and the edge of the chip? Is this is good idea? It's the only location I can think of to get a consistent measure before and after. The sensor is very thin. Or perhaps I can somehow glue it on that little edge where the heatink doesn't touch the chip as an alternative?

Right now for testing purposes I've put a sensor between the fans of the heatsink and the readout is 44 °C.